Expert Solutions for Consistency, Vibration, and Jamming in Your Pitching Machine

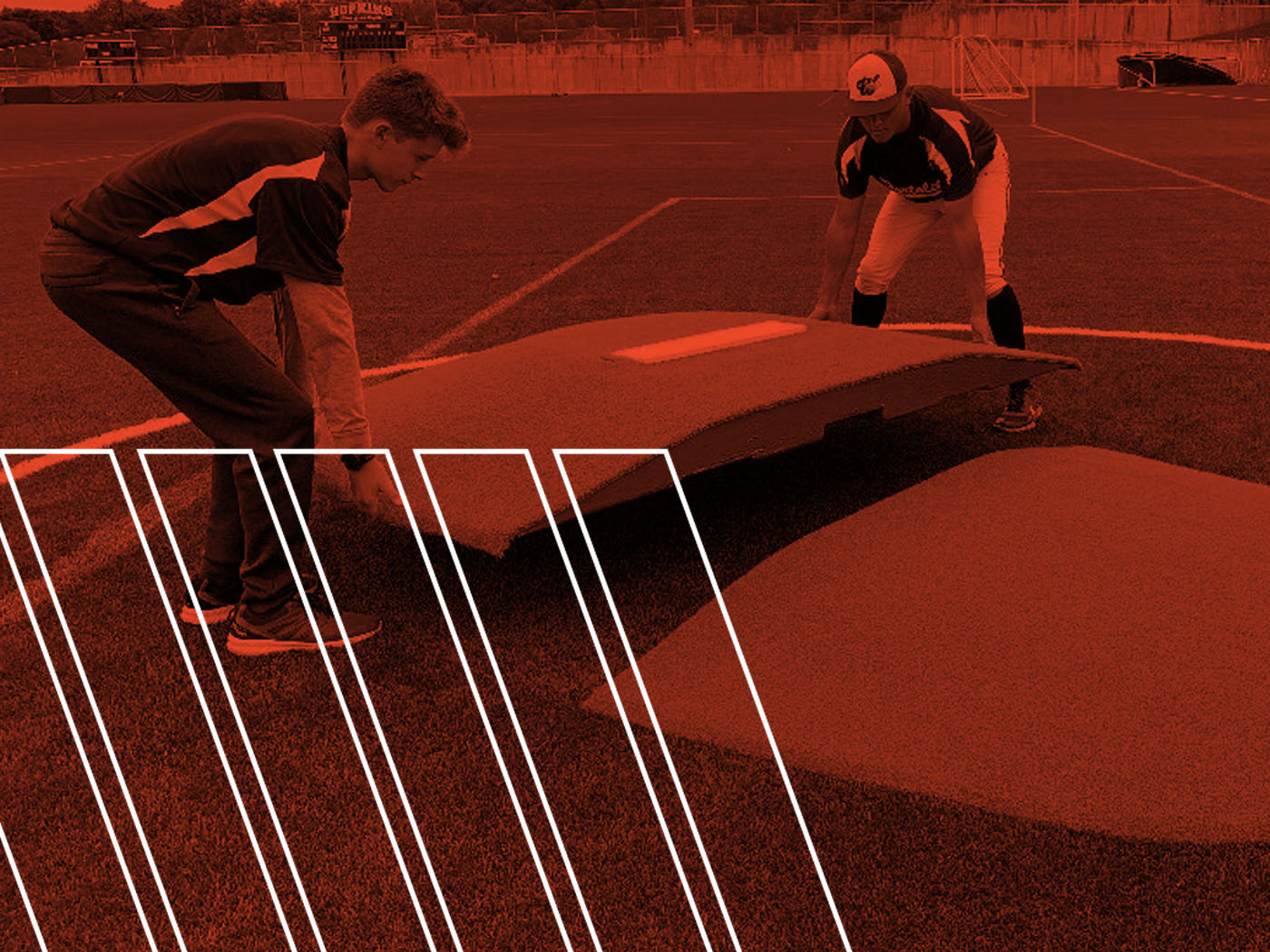

Welcome to the essential guide for diagnosing and fixing your pitching machine. Whether you're a coach, player, or enthusiast, understanding how to maintain and troubleshoot your pitching machine is key to a seamless and safe pitching machine training experience.

What You Will Learn

Inconsistent pitches, jamming issues, and unexpected breakdowns can disrupt even the most well-planned training sessions. In this guide, we delve into the common issues that arise with pitching machines and provide practical solutions to ensure your machine performs consistently, pitch after pitch. Get ready to transform your training sessions with these expert tips and insights.

"To ensure a smooth and consistent batting practice, stick to the same brand of machine balls specifically designed for pitching machine use, and keep them relatively clean."

Common Issues with Pitching Machines

Pitching machines, like any mechanical equipment, can encounter various technical issues. Understanding these common problems is key to a quick resolution and uninterrupted practice sessions.

1. Inconsistent Pitches: One frequent issue is inconsistent pitch delivery. For instance, users of the JUGS pitching machines often report varying pitch speeds or unexpected pitch types during a session. This inconsistency can stem from calibration errors, mechanical wear, and worn out balls.

2. Jamming and Blockages: Another common problem, especially in older or heavily used machines like the ATEC models, is ball jamming. This often occurs due to dirt accumulation or misalignment of feeding mechanisms.

3. Noise and Vibrations: Excessive noise or vibration, a complaint often associated with brands like Heater, can indicate loose components or internal misalignments.

Other Common Issues

Electrical Issues: The majority of modern day pitching machines feature some sort of electrical equipment. Because of this, they may experience control panel malfunctions or power supply issues, leading to erratic operation. For these types of issues, we recommend calling the manufacturer or returning the machine. We do not recommend trying to fix this issue yourself.

Problem #1 - Inconsistent Pitches: Causes and Solutions

Inconsistent pitches disrupt the rhythm of batting practice and hinder skill development. There are a few reasons why a pitching machine may throw inconsistent pitches. Let's take a look at the most common reasons:

Solutions

- Low Tire Pressure: If your machine uses an inflatable wheel, make sure the wheel is inflated to the specified psi. Otherwise, you may experience inconsistent pitch speeds.

- Ball Quality: A primary cause for erratic pitching is often the balls themselves. Using balls that are either dirty or don't align with your machine's specifications can lead to inconsistent pitches. Moreover, alternating between various types of balls during practice is a surefire way to create irregularities. To ensure a smooth and consistent batting practice, stick to the same brand of machine balls specifically designed for pitching machine use, and keep them relatively clean.

- Mechanical Check-up: Inconsistent pitches in machines like the Iron Mike could indicate wear and tear. Regular inspection and replacement of worn-out parts can maintain consistency.

- Manual Feed Caution: When manually loading balls into the pitching machine, it's crucial to allow up to 10 seconds between pitches. This pause ensures the wheels regain their full speed. Feeding balls too rapidly can lead to inconsistent pitch quality.

- Battery Maintenance: For battery-operated machines like Zooka, regular charging and timely battery replacement are crucial. Low batteries can lead to poor machine performance.

Problem #2 - Dealing with Jamming and Mechanical Failures

Jamming is a common annoyance, particularly in machines with automatic feeding mechanisms. Pitching machine users have reported occasional ball jamming due to misalignment in the feeding chute or the presence of dirt and debris. Let's take a look at some of the most common causes and solutions of jamming.

Solutions

- Regular Cleaning: Keeping the machine clean, especially the ball chute, feeding mechanism and wheels, can prevent jamming. This involves wiping down surfaces and removing any accumulated dirt or debris.

- Proper Alignment: Ensure all parts are correctly aligned. For machines with an automatic ball feeder, make sure the feeder chute is properly aligned with the chute opening.

- Quality of Balls: Using the recommended type and quality of balls, as lower quality balls can deform and cause blockages. Also, ensure the balls are clean to reduce dirtying the chute and machine wheels.

Problem #3 - Resolving Noise and Vibration Issues

Excessive noise and vibration in a pitching machine can be more than just a nuisance; they often indicate underlying mechanical issues. For instance, the Heater pitching machines are sometimes reported to develop such problems due to loose components or aging motors. Let's take a look at some of the most common noise and vibration issues and some tips on troubleshooting them.

Tips and Solutions

-

Tighten Loose Components:

- Solution: Regularly inspect and tighten any loose bolts or screws. Vibrations often arise from parts that have become loose over time. For example, tightening the bolts on the wheel housing can significantly reduce noise in most machines.

-

Lubrication of Moving Parts:

- Solution: Proper lubrication of moving parts, such as pivot points and wheel axles, can reduce friction, thereby decreasing noise and vibrations.

-

Motor Maintenance:

- Solution: Noisy operation can sometimes be attributed to motor issues. Regular maintenance or replacement of worn-out motors is crucial, especially in older machines. We recommend contacting the manufacturer to resolve these kinds of issues.

-

Balancing the Wheels:

- Solution: Unbalanced wheels can cause significant vibrations. Ensuring that the wheels are properly aligned and balanced is key. You may need to remove the wheel and take it to a tire shop to be balanced.

-

Dampening Vibrations:

- Solution: Using vibration dampening materials like rubber mats under the machine can help absorb and reduce noise.

Noise and vibrations in pitching machines should not be overlooked, as they can affect both the machine's performance and the user's experience. Regular maintenance, proper alignment, and timely repairs are crucial for ensuring smooth and quiet operation. Implementing these solutions can extend the lifespan of your machine and enhance your training sessions.

Conclusion

As we conclude this comprehensive guide on troubleshooting common pitching machine issues, remember that the key to a reliable and effective training session lies in understanding your machine and its maintenance needs. Regular upkeep, proper usage, and timely troubleshooting can dramatically enhance the performance and longevity of your pitching machine.

Contact Us

Contact Us